Description

Micro-Adjustable .19 cal Neck Turner | Neck Turning Tool

The K&M neck turner has a very unique cutter adjustment mechanism that allows for a very precise cutter adjustment. This design incorporates very fine pitched threads of a screw within a screw concept which yields 0.002” cutter advance for each rotation of the adjustment nut. As a point of reference and comparison, a micrometer advances the spindle 0.025” for every revolution of the thimble. There are etched markers on the neck turner body around the circumference of the cutter adjustment screw hole placed every 30 degrees radially and as a reference, there is one punch mark on the face of the adjustment nut. When the adjustment nut is rotated one increment the cutter advancement is 0.0002”.

You can drive the cartridge with the power adapter and proper shell holder by hand when the handle is installed or remove the handle from the power adapter and insert the ¼” hex stem into a cordless screwdriver.

Use the SHELL HOLDER # GUIDE to determine the appropriate Shell Holder for your particular application.

Doughnut Control

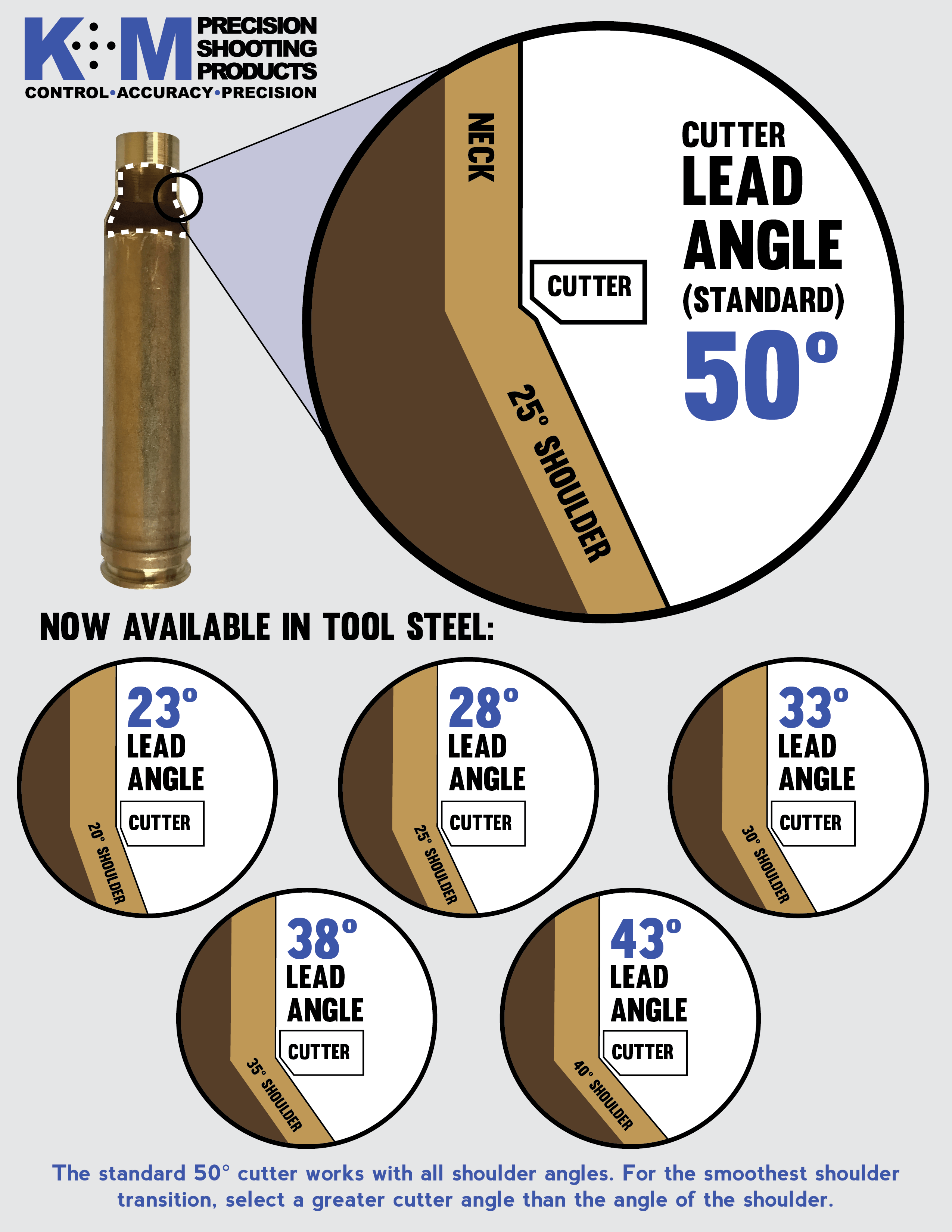

To properly combat the formation of a doughnut the neck should be turned so the cut ends slightly into the shoulder. Our cutter lead angle will accommodate all shoulder angles by allowing you to cut into the neck/shoulder junction while the leading angle “blends out” of the shoulder.

Tool Notes:

Neck Turner Assembled with Pilot & Shell Holder

If you purchased your neck turner kit directly from K&M, it will be assembled with the pilot and shell holder you specify and the cutter will be positioned so you can make your final depth of cut for neck thickness adjustment. Of course, you will also need to make the final pilot position adjustment for your preferred depth of cut into the shoulder.

Adjustment of Pilot for Neck Turning Tool

If you purchased your neck turner without a pilot, or need to change the pilot for another caliber you more than likely will need to make a coarse adjustment on the cutter position. Keep in mind that once the outer adjustment nut is engaged in the blue body there is only 0.025-0.050” of cutter movement available. To make a coarse adjustment first loosen the cutter clamp screw and rotate the adjustment nut counter-clockwise until the adjustment nut is free from the body. Don’t pull the cutter assembly completely from the body, but if you do and didn’t make note of the orientation refer to the “Neck Turner Cutter Orientation” pdf document above. Now pull the assembly back just far enough so the adjustment nut is not making contact with the body and rotate the adjustment nut clockwise, this will suck the cutter into the adjusting nut (away from the pilot). When the end of the cutter is clear of the pilot hole in the neck turner body install the pilot into the body and lock it down. Now apply gentle pressure to the adjuster nut against the body and rotate it counter-clockwise until the cutter tip is in that 0.025-0.050” distance from the pilot. You will feel the lead of the thread “click” once each revolution as they pass.

Setting the Cutter Depth

Next re-engage the adjustment nut in the body by rotating clockwise until you achieve your desired depth of cut into the cartridge neck wall. These are very fine threads so take care not to cross-thread them. We purposely make the thread fit tight to minimize backlash but it is always good practice to make your depth of cut adjustments “into the cut”. If you go too far, back the cutter out of the cut and start over rather than making depth adjustments “out of the cut”. The washer under the cutter clamp screw is a spherical spring washer so while you are making your set-up adjustments keep light pressure on the washer which maintains some clamping pressure on the cutter. Once you have achieved your target wall thickness lock this screw down. Please be careful and do not advance the cutter into the pilot which will easily damage the cutting edge.

Procedure for Turning Necks

The generally accepted procedure for turning necks is to first size your brass, full-length sizing is usually preferable in preparation for turning. Next, be sure your brass is trimmed to the specified length and expand the neck with a K&M expand iron (don’t skip this step as the expand mandrel is proportionally sized to the pilot to account for brass spring back). Now lock the cartridge in the power adapter and turn the neck all the way and slightly into the shoulder which will help to control the formation of a doughnut in the future. If you choose to turn the cartridge under power it is best to choose a cordless screwdriver that typically has lower max speeds than a drill. Turning at high speed will generate heat which will effect dimensional control and risk galling brass onto the pilot. A good technique is to make two passes with the neck turner, patiently feeding all the way to the shoulder and then patiently back feed all the way off the neck. Clear any chips after each pass and use a good lubricant such as Imperial Die Sizing wax on both the expand mandrel and pilot.

Optional Accessories for the K+M Neck Turning Tool

Consider some of the neck turner accessories to make the job more enjoyable. The Pilot Jack is a slick little device that clamps onto the bottom of the neck turner body which incorporates a thumb screw that butts against the shank end of the pilot which in turn allows you to easily meter the position of the pilot when setting the tool up. Of course, the position of the pilot is important because the case mouth bottoms on the step ground into the pilot which is the physical stop for how far you turn into the shoulder.

The Ergo Holder really makes holding the neck turner enjoyable when you set down to turn large lots of brass. If you plan to use the dial indicator with the neck turner to measure wall thickness the Ergo Holder is a wise investment.

Available Pilots for the K+M Micro-Adjustable Neck Turner

The Pilots that we stock for the Micro-Adjustable Neck Turner are as follows: Tool Steel: .17, .19, .20, .22, 6mm, .25, 6.5mm, .270, 7mm, .30, .311, .32, 8mm, .338 Carbide Cutting: .17, .19 (limited qty), .20, .22, 6mm, .25, 6.5mm, .270, 7mm, .30, 8mm, .338 Carbide Non-Cutting: .17, .20, .22, 6mm, .25, 6.5mm, .270, 7mm, .30, .338 Some sizes are not available through the website, please call for further details.

Reviews

There are no reviews yet.