Description

Professional Flash Hole Uniformer

Hand Loader! Are you looking for improved accuracy? Accuracy demands consistency and precision in every operation and component used in hand loading. The brass case is very important and sometimes important details are overlooked–such as the Primer Pocket and Flash Hole inside of the case.

In cartridge manufacturing, the flash hole is “punched” into the brass. While this is the least expensive method, it has many shortcomings and inconsistencies. The flash holes, therefore, are of different sizes and shapes. The most detrimental to accuracy are the irregular “breakouts” and “burrs” on the inside. This will cause “shot-to-shot” differences in Primer “Flame Fronts”, causing inconsistent pressure/velocity and, thereby, loss of accuracy. Bench Rest Shooters have been uniforming flash holes since 1969.

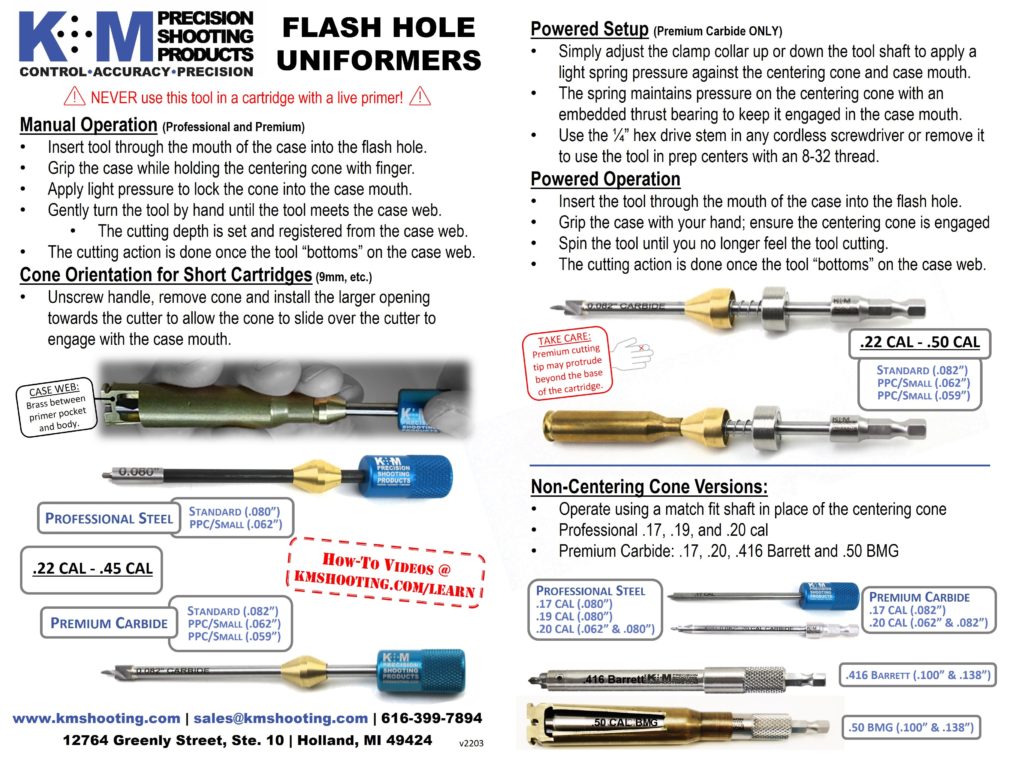

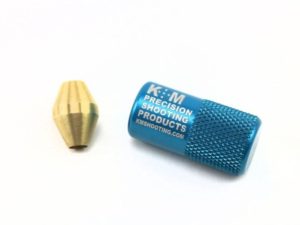

With the Precision K & M UNIFORMER tools, you can realize the potential accuracy by simultaneously reaming, de-burring and chamfering the inside of the flash hole. The unique features of the K & M Tools provide uniformity with a pre-set depth stop, (Gage), surrounding the tool steel cutter, therefore, does not require the case to be trimmed to a precise or consistent length. Operation is controlled in reference to inside-bottom of case, not case mouth.

Tool Notes:

NEVER use these tools in a case with a live Primer De-Cap Case – insert the K & M uniformer through the mouth of the case into the flash hole- grip case, with the base in the palm of hand, while holding the centering cone with thumb and forefinger apply light pressure to lock the cone into the case mouth. Gently turn the tool. You can feel the work being done. The cutting will cease when the Pre-set Depth Gage comes in contact with the inside bottom of case. Each one will feel different as you cut away the burrs and provide the 60° chamfer.

6 reviews for Professional Steel Flash Hole Uniformer Tool

There are no reviews yet.