Description

• NEVER use these tools in a case with a “LIVE Primer”.

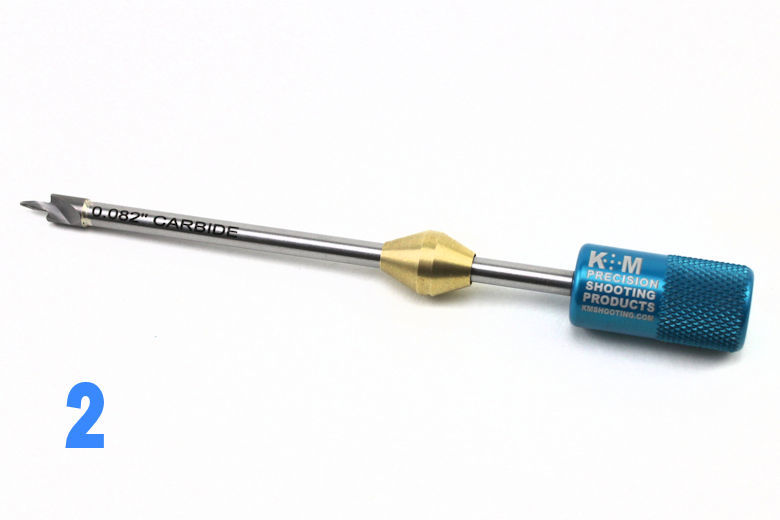

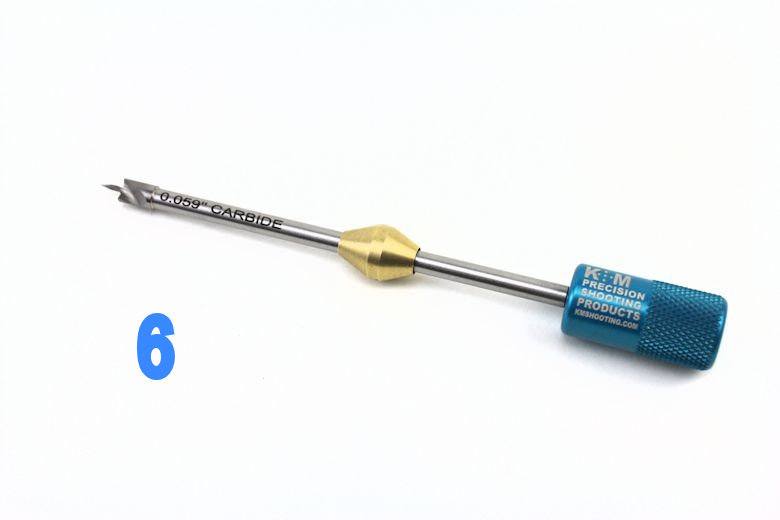

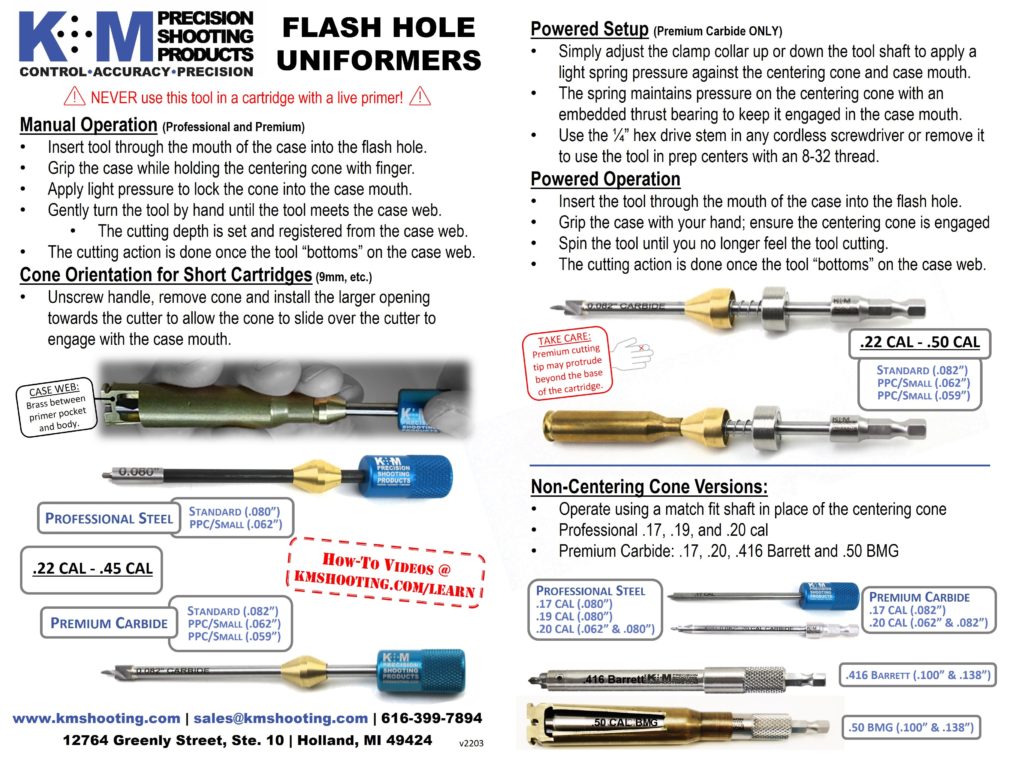

•The new Premium flash hole tools have a carbide cutting head that allow the brass chips to free flow from the cutter which conditions both the diameter of the flash hole and chamfers the flash hole at the case web.

•Available in 0.082”, 0.062” and 0.059” diameter cutting tips.

•The tip of the tool has a gentle taper to help enter the flash hole and then condition the flash hole to a specific diameter.

•Just as our “Professional” flash hole tool, the “Premium” tool chamfer cut depth is controlled from the case web. So once the tool bottoms on the case web the cutting action is done regardless of overall case length variation.

•Available in configurations for manual and powered operation.

• Insert the Premium for Manual Operation tool through the mouth of the case into the flash hole and grip the case with your hand while holding the brass centering cone in the case mouth to maintain the tool to the centerline of the cartridge. Rotate the tool handle with the other hand until you no longer feel the tool cutting. TAKE CARE as the cutting tip will protrude beyond the base of the cartridge.

•If you prefer to use the tool driven with power then select the Premium for Powered Operation configuration. A thrust bearing is embedded in the centering cone in which a spring maintains pressure on the cone to keep it engaged in the case mouth. Simply adjust the clamp collar up or down the tool shaft to apply a light spring pressure against the centering cone. Use the ¼” hex drive stem in any cordless screw driver or remove it so the tool can be used in prep centers with an 8-32 thread.

•When your tool is in storage wipe a light oil on the tool steel shaft.

Casey Urrutia (verified owner) –

I bought this mainly to see if I could take care of some small flash hole foreign brass. Consistent flash holes weren’t a bad thing, either, for the rest of my brass. But this thing worked great to open up those small flash holes. Now my decapping pins won’t break!

Dave @ K&M –

Glad its working well for you Casey; thanks for the review!

Kim Giles (verified owner) –

I originally bought the non powered version from Midway and I loved it but after doing a couple of hundred cases I realized I needed a powered version.

This thing is amazing it will deburr the flash hole and open it up in no time flat. Perfect every time.

Everything I have bought from K&M is perfection. Well worth the investment.

Dave @ K&M –

Thanks for the review Kim – glad you’re enjoying the ease of the powered version!

Yves Fotsch (verified owner) –

Wrote the same review for another tool I purchased from Dave @ K&M. I can not emphasize more than if you found K&M you found the “X”. Quality and customer service will rock you into a whole new world. So here it goes:

First: Can we just clone Dave. Professional, yet relaxed; open-minded yet decisive; Dave can always be approached with any question. Whether trivial or of utmost importance, he always has a measured and professional response.

Second: The tool … don’t get me started (I’ll write a book). Top notch quality proudly made in the USA. In my ignorance I spent a lot of money on some other brands only to give them away after getting my hands on tools from K&M.

Dave @ K&M –

Thanks for the review (2x) Yves! We’re here to serve; glad we hit the mark!

Scott Sorensen (verified owner) –

This is a great tool,cuts perfect flash holes. I’m very impressed.

Dave @ K&M (verified owner) –

Thanks for review Scott. I’m glad it’s working well for you!

Scott Verzwyvelt (verified owner) –

Processed (200) 308 Winchester brass pieces with manual device worked great but was hard on my hand muscles. I bought a powered unit breezed through (200) 270 Winchester cases. Works great!

Dave @ K&M (verified owner) –

Thanks for the review Scott. I’m glad it’s working well for you and giving your hand a break!