Description

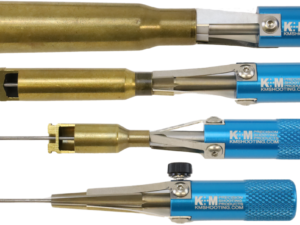

Controlled Depth Tapered Reamer .416 – .50 BMG Cal. – Reloading Chamfer Tool

The K&M case mouth chamfer tool cuts a shallow angle chamfer on the inside of the case neck for smooth bullet seating while controlling the depth of cut with stop fingers that register on the case mouth which insures each case has the same depth chamfer. The chamfer angle is 4 degrees per side. The tool also incorporates a pilot pin that guides through the flash hole of the cartridge to maintain the tool on the centerline of the cartridge for an even cut. The tools cut chatterless by means of a 6-flute cutting design except for the .17cal-6mm tool which is a 3-flute tool. We now have 5 tools in the line up to accommodate calibers .17 through .50 caliber.

- .17cal – 6mm Calibers

- 6mm – .338 Calibers

- .35 – .408 Calibers

- .416 – .50 calibers

- .416 – .50 Calibers, BMG Cartridges base only

Tool Notes:

- Size your brass before using this reloading chamfer tool to ensure that the case mouth inside diameter is consistent and perfectly round.

- Loosen the thumbscrew and use a small flat blade screwdriver to adjust the set screw in the handle to move the cutter within the tool body. It is best to start with the cutter set so it is not touching the case mouth and begin inching it forward with the set screw until you just make contact with the case mouth, now advance the cutter forward until the desired chamfer depth is attained and tighten the thumbscrew.

- Typical chamfer depth is .015”-.030”.

- The cutter is sharp so remove material gently until the stop fingers make contact with the case mouth. This usually only takes 2 or 3 revolutions between your thumb and forefinger.

- Bullet will now seat smoothly with its base unharmed.

Richard Biggio (verified owner) –

Another great tool for preparing consistent brass!. This tool is easily and precisely adjusted for depth of chamfer. I used a case that was neck-turned, sized, trimmed, and expanded neck with a custom mandrel. You need to do this prep on a case exactly the way your going to load it. This allowed an accurate Datum for setting the depth of chamfer. With the locking knob loose, and the adjusting screw slacked off, I was able to insert the tool and just make blade contact with the ID of the neck. Then carefully I screwed the adjusting screw in to raise the stop fins above the mouth of the case. I measured the gap with a feeler gauge, to determine my desired depth. I took less time than typing this review! 🙂 Thanks K & M for this tool.

Dave @ K&M –

Thanks for the review and your business Richard! I’m glad it’s working well for you.