Description

Expand Mandrels for Bullet Tension:

For custom expand mandrels please e-mail to order.

.22, 6mm, 6.5mm, .270, 7mm, .30, .338, .375, .416, .45 and .50 cal

(*some sizes may still have the threaded hole as we deplete inventory)

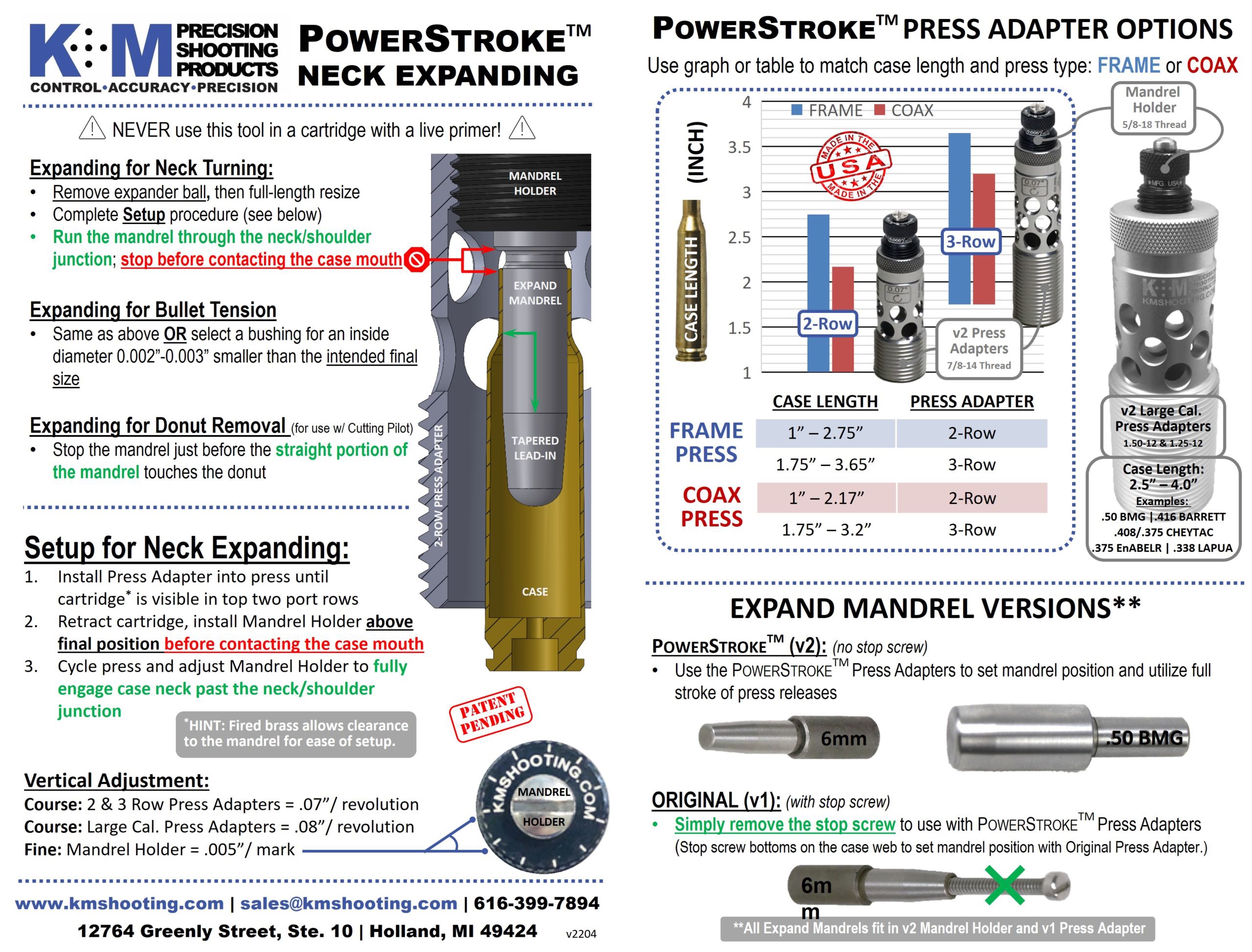

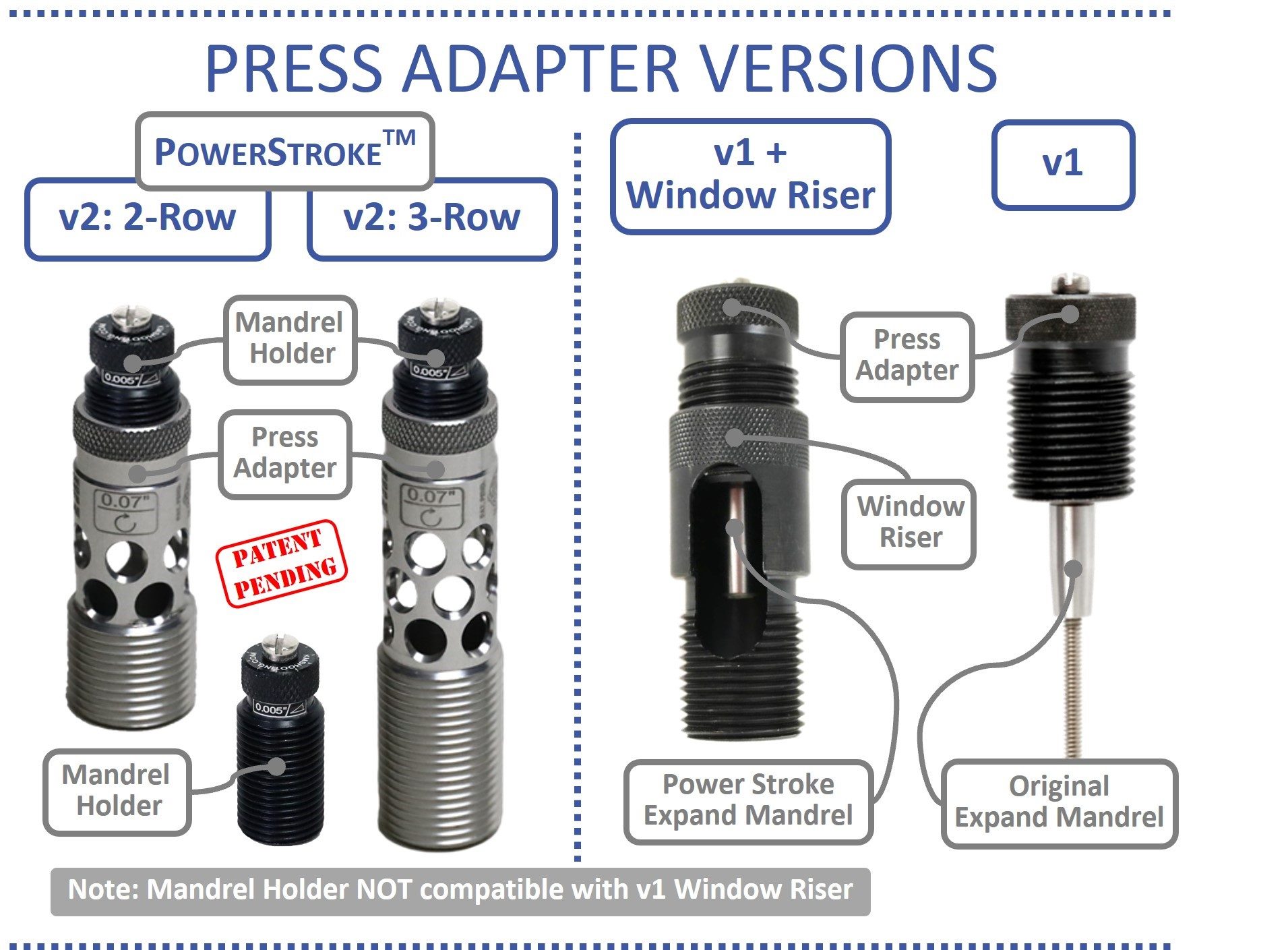

PowerStroke™ expand mandrels require a v1 Window Riser or v2 Press Adapter

help me choose.

Tool Notes: Download Tool Instructions

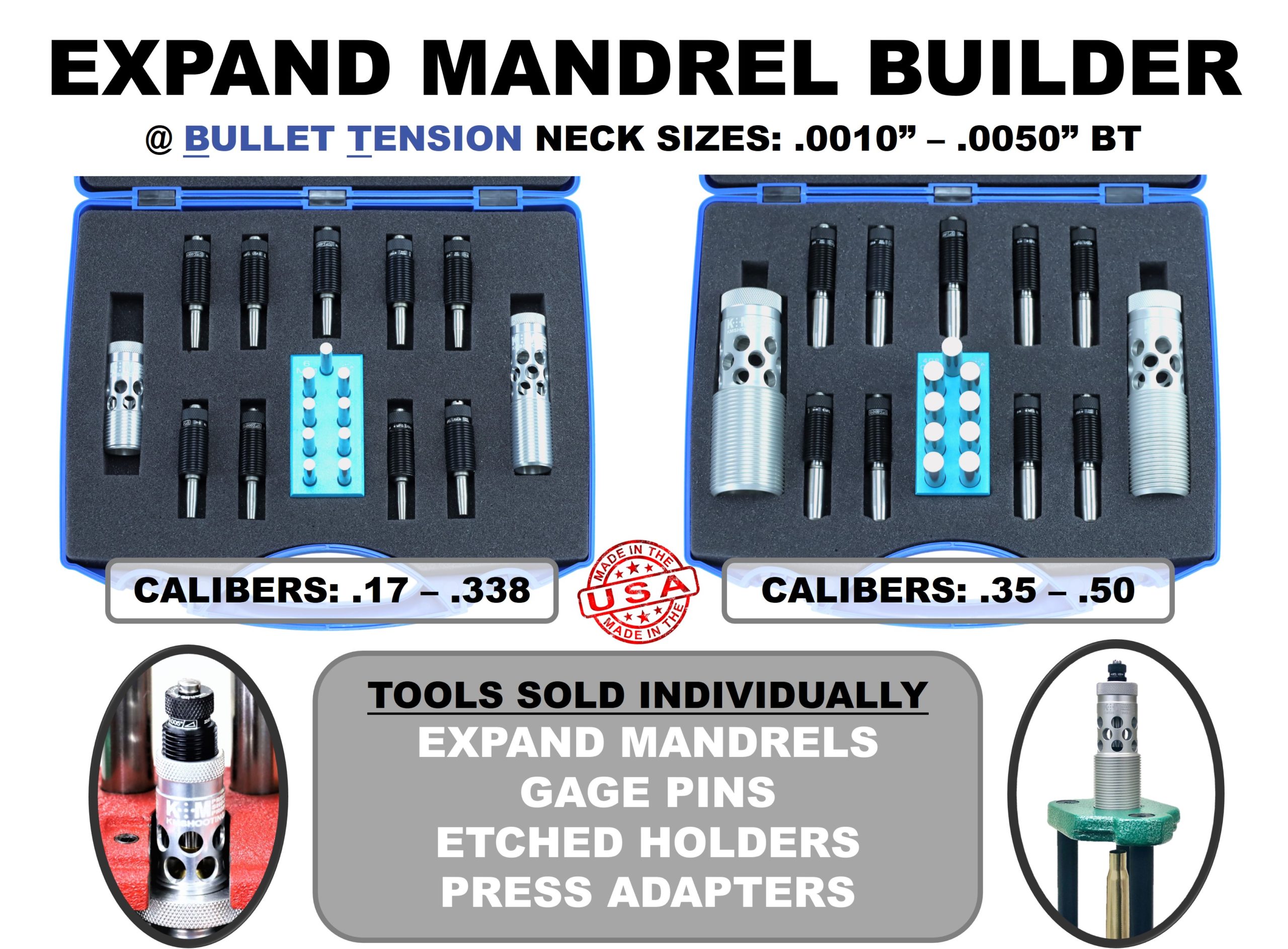

After selecting the caliber, select each bullet tension expand mandrel desired for your kit. Each selection allows for selecting an etched press adapter and the corresponding gage pin for that neck tension. Both the expand mandrel and the press adapter are laser-etched with the caliber and the bullet tension for easy identification. The gage pin block will be etched with the caliber and each gage pin location will be noted with the bullet tension and the diameter of the gage pin. All of our expand mandrels are ground oversize to account for spring-back of brass which is assumed at the nominal anneal.

When using an expand mandrel to achieve final neck sizing bullet tension we find it best to size your neck 0.002” to 0.003” below your desired final bullet tension size. For example, say you are working with a 7mm caliber (0.284”) and you would like 0.004” of bullet tension. Subtract the 0.004” from the standard bullet diameter, 0.284”-0.004”=0.280”, this will be the final size after expanding. However, the neck inside diameter needs to be slightly smaller so the expand mandrel can properly size the brass. Now subtract the 0.002” or 0.003” from the final size, 0.280”-0.003”=0.277”. Now based on your neck wall thickness select the appropriate bushing that will achieve the 0.277” inside neck diameter. Once this sizing is complete perform the final sizing of the neck with the expand mandrel. Be sure to at least use a light lubricant. Alternatively, you can use a traditional full-length die (expander ball removed) and use the expand mandrel for final sizing.

Checking your Case Neck with Gage Pin:

After expanding use the corresponding gage pin to confirm the neck sized as expected. The feel you are looking for is a light drag on the gage pin. When sized properly the gage pin will act as a piston as you push the pin into the case neck while holding your finger or thumb over the primer pocket. You can actually feel the air compress inside the case. Quite often the brass can be harder or softer than expected. By stepping up or down on the expand mandrel bullet tension size you can achieve the desired neck tension to your pin gage.

Ted –

22-30 cal tapered expander custom mandrel

I have loaded many wildcat calibers over the years starting years ago with the TC/U wildcats of Ugalde and others. Reloading dies at the time offered tapered expander to make 6.5mm and 7mm mouths from available 223 brass. Today the same procedure exists with the newer 300 BlackoutAAC and Whisper. My Hornady New Dimentions dies include a tapered expander ball but I needed an external method. I spoke with Roger at K&M and he obliged me with retuning his standard 7mm-30 cal mandrel. I am very pleased with the finished product which allows full trimming in my Redding Form/Trim die or my 300B.O. Jig with chop saw. This is fast and efficient, and so far; no lost cases from expanding. I lube the internal necks of either 222 Rem/.223 Rem, or 221 FB with this tapered mandrel.Great job Roger and K&M.

Greg Cotterell –

.50 cal tapered custom expand mandrels and gage pins

I shoot 50 cal competition and was running into variable bullet tension problems, in large part due to inconsistent annealing, which I am working on. I full length re-size after each shoot and have used both Hornady and CH4D dies with included expander balls. However, these expander balls are only .507 in diameter, and with the the variable “spring back” I was getting bullet tensions were too high and too variable to achieve an accurately uniform set of cartridges to shoot a two gun match. I emailed K+M and worked with Dave Allen to determine an appropriate set of stem expander mandrels along with a set of gage pins to achieve a bullet tension of .002″. The K+M mandrels and gage pins I receive are of high precision, each mandrel and pin mic’ed to the exact dimensions printed on the sides. I removed the ball expander from my CH4D FL die to size all of the brass. I then used my RCBS Ammomaster for 50 BMG with the mandrel mounted in my adapter. Although I was not able to use the current K+M extender to obtain a full stroke of the ram, I was still able to fully expand the necks of my casings. I have worked on improving the annealing process, and with the expand mandrels, I was able to achieve a neck ID of .508″ (the necks would not pass the .5085 pin) in 145 cases out of 157 that were annealed. The “spring back” I had was roughly .0015″ in 133 of the cases. I will simple rework the dozen cases that were over-sized. Dave is wonderful to work with, understanding the process involved and able to communicate his knowledge well, and I was able to achieve the appropriate size coverage with only four mandrels and associated gage pins. I couldn’t be more pleased with these custom expand mandrels and gage pins. And I understand that K+M is also working on an expand mandrel riser for use with the large caliber brass, which will be a welcome addition allowing a full ram extension.

Dave @ K&M –

Hey Greg, thanks for the kind words and thorough review! The large-cal window riser is through the first prototype and now working on design updates for rev 2. Hopefully we’ll have this out before 2022 (or 2023 in these crazy times!).

Jeff Lovat (verified owner) –

Already possessed the neck turner 223 mandrel which I bought before I knew what I was doing then discovered I needed the neck tension mandrels. SO this time I called and chatted with KM and trust me, I am a slow learner and they were very patient with me and suggested what I needed based upon the conversation. Then I called back again and they again patiently listened and advised and counseled on what I needed with my new questions and I ended up ordering the .003 and .004 neck tension mandrels for 223 and am very happy with them and they are doing the job I expect of them. Love supporting an American small business and especially with such nice and patient customer service. Speaking of, no waiting to talk to a real person also.

Roger Miller –

Thanks for the review Jeff! Glad we could help get you setup.

huang_wan (verified owner) –

Every product I have purchased has been of the highest quality. I worked with them to get proper tension for my 50 BMG and the mandril is spot on for my brass. In addition to good products they have great customer service. I will continue to use their version of the tools I use to help me shoot accurately.

Dave @ K&M (verified owner) –

RH, thanks for the review! I appreciate your input here, by e-mail, and discussions on the phone.